Engineering Services

Engineering & Consulting Services

We offer a variety of engineering services, including principal engineering and advanced analysis, engineering consulting, product rendering and reverse engineering.

Overview of offerings:

Product rendering

CAD Modeling

Engineering drawing

Mechanical engineering drawing

Design prototype

Sketch prototype

GD&T

Tooling Design

Wiring harness diagram

Wiring harness schematic

Vehicle design

Collaborative design

Sketch Prototype Services

If you are in the concept stage of your new product invention, you’re likely looking for a professional sketch of your prototype. Not all inventors have the artistic capacity or the product rendering experience to be able to draw their own professional sketches. We will consult with you on the business aspect of your product, while also fulfilling your prototype rendering needs. We’ll often begin with a sketch of your prototype, followed by a proper product rendering, likely as a CAD model, then finally an engineering schematic that will allow for production

Engineering Drawings and CAD Modeling

Once you are ready to begin the technical analysis of your product, you will surely need proper engineering drawings in the form of a CAD model, CAM model, mechanical engineering drawing, and/or engineering schematic with GD&T. We’ll work with you to let you know which types of drawings you will need.

Affordable Product Renders

We can help you save on costs that you may have spent by paying expensive patent attorneys, or investment firms who you need to work with to launch your business. Many new inventors will pay for sketches and product renders from several different service providers. By getting your initial sketches and renders with us, you can use the generated CAD models or drawings for your patent applications, business plans or investor pitch-deck initially, then build upon them to create detailed drawings and plans when appropriate.

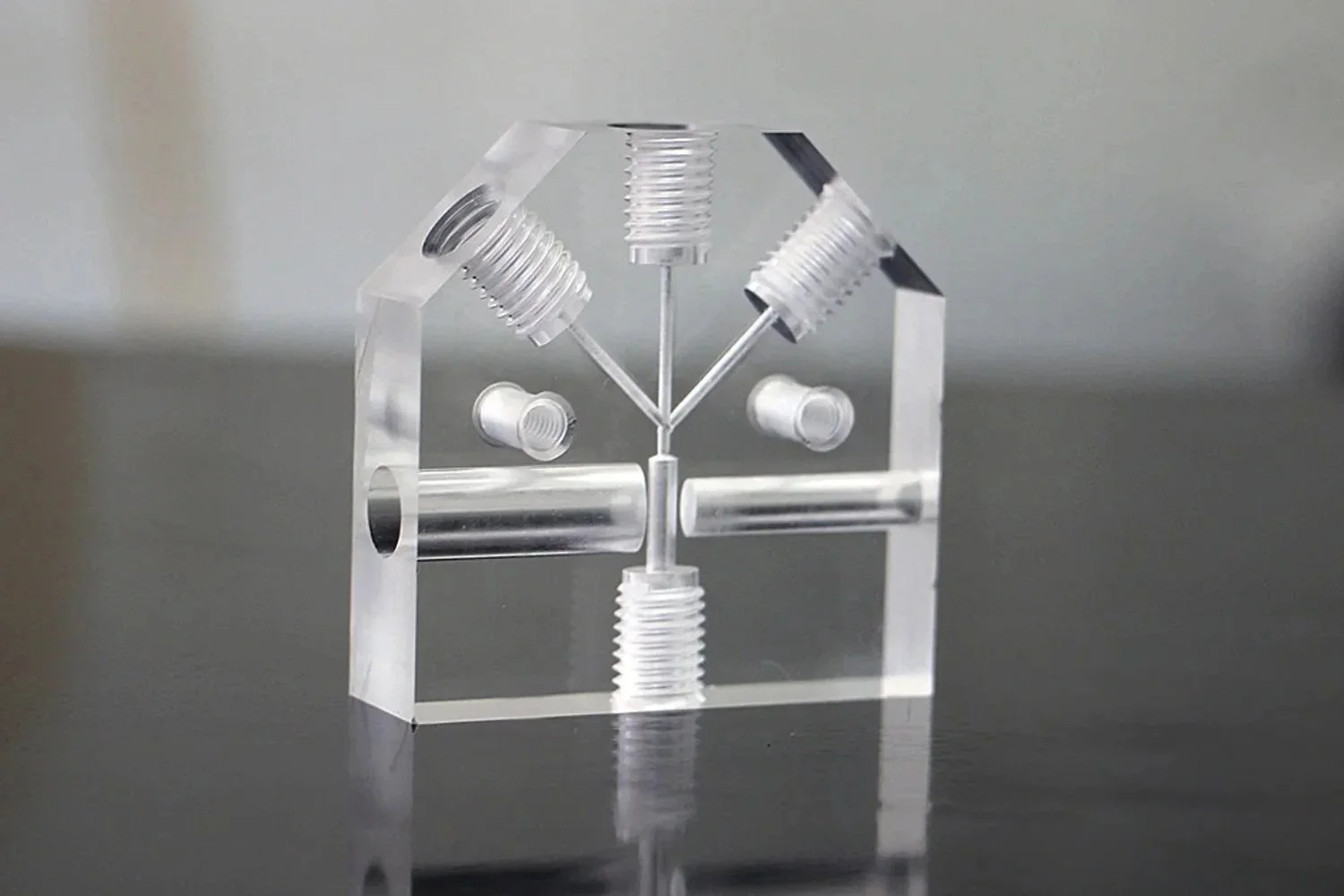

Reverse Engineering

New Product Consulting

Principal & Advanced Engineering Analysis

We perform system-level and structural analysis using first-principles methods and simulation tools to validate designs and ensure performance for electromechanical, automotive, and complex mechanical systems.

System and Structural Analysis

Our engineers have experience in system analysis. We use software such as MATLAB, AMESon and VALDYN to perform systems level simulations for your specific product.

Our broad experience across many engineering fields will help us to amend and improve your new product in the initial stages of development. If we see obvious design flaws or mechanical deficiencies, we will highlight these for you well before going into the product rendering stage.

CAD Model & CAM Model Consulting

We develop production-ready CAD models, CAM data, engineering drawings, and GD&T to support design validation, prototyping, and manufacturing.

Prototype and Manufacturing Consultation

Once again, we offer our expert consultations at every step of the product development process. Once your initial prototype is complete, we can help draft a test plan to make sure your product lives up to its requirements. We can help you with UL certification, and putting you in touch with testers and/or suppliers.

Product Rendering Services

Obtaining an accurate product rendering is one of the most important first steps in product development. You may need a prototype sketch for legal, financial and especially manufacturing purposes. We can help you get accurate product renders while minimizing costs.

Reverse engineering has many applications across many fields including engineering, electronics, consumer products, microchips and automotive. It’s frequently used in new product manufacturing, design and reproduction. And with the increasing popularity of 3D printing, we expect to see an even greater demand for reverse engineering in the upcoming decade.

There are several scenarios that will produce a need to reverse engineering:

You want to replicate or alter a product, however the original manufacturer no longer exists or no longer makes said product

There is no original design documentation or CAD data for the item you are trying to engineer

You want to perform analysis on a product for which you don’t have a CAD model

There is a model or sculpture (possibly made of clay, plaster, wood or foam) that you hope to recreate, modify or scale

Here at MWW1, we believe that the ability to reverse engineer has many competitive advantages in today’s market. Most commonly, reverse engineering is utilized to reduce the length of time in product development. If rapid product development (RPD) is a requirement for your business, we can discuss how reverse engineering may benefit you.

Vehicle Garage Services

Our new facility features a 10,000lb 2 post vehicle lift, and supporting tools and equipment necessary to service our customers vehicle integration needs. We are experienced in adapting engine, electric motor, and transmission powertrain components to passenger car & commercial vehicles alike. We have onsite metal fabrication facilities as well as a full service machine shop to help ensure we can quickly & successfully execute your vehicle integration project.